Pull it

Introduction

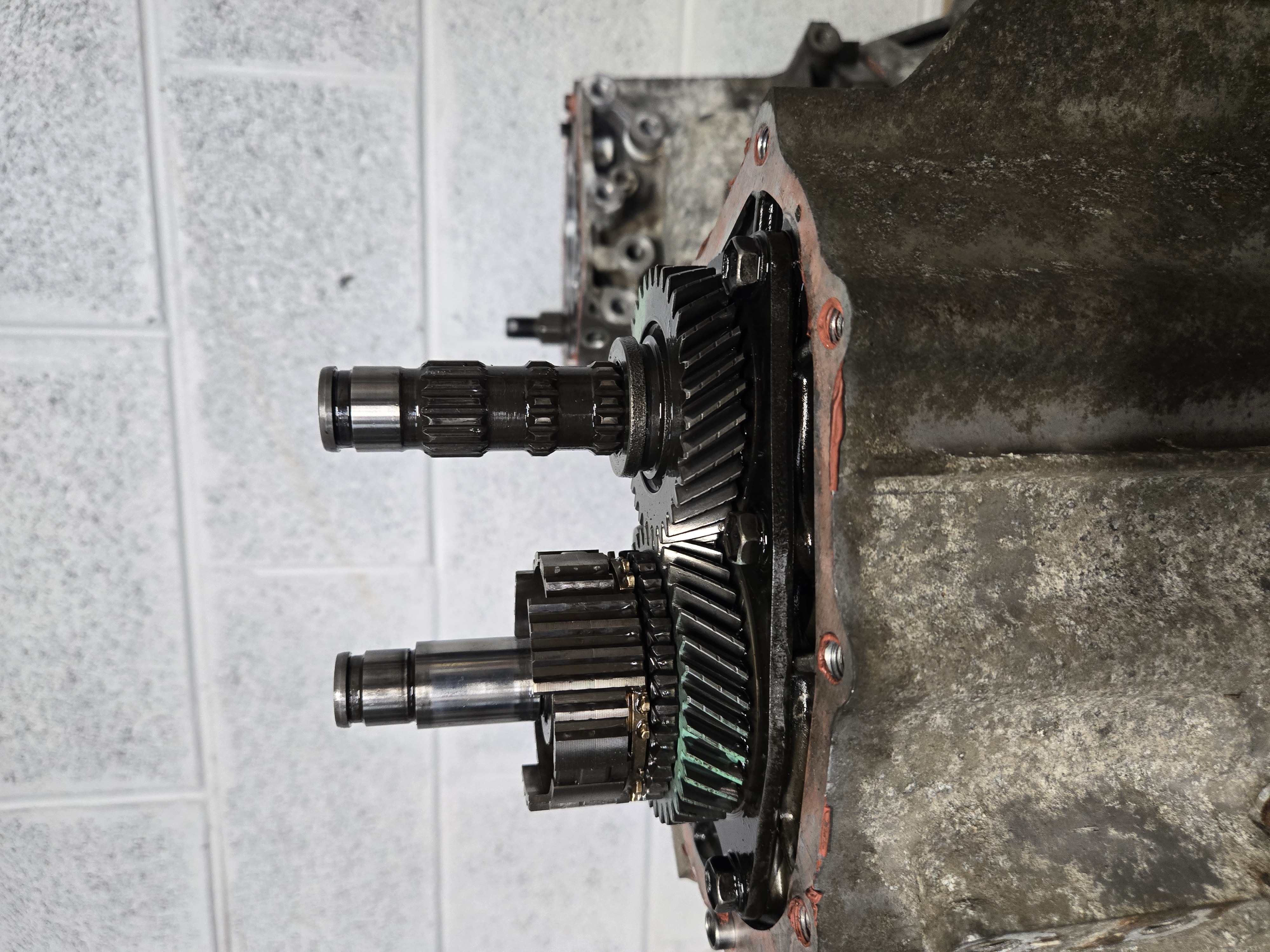

I recently found myself pulling apart a few Toyota C-series transmissions to construct a six speed transmission with a limited slip differential for installation into my AW11 Toyota MR2. The C-series has a few operations which are prone to cracking gears. After assembling a few of these transmissions I have grown a distate for universal gear pullers. I decided to take a stab at designing a gear puller.

Design

I modeled the gear to be pulled and keep out areas in Autodesk Fusion.

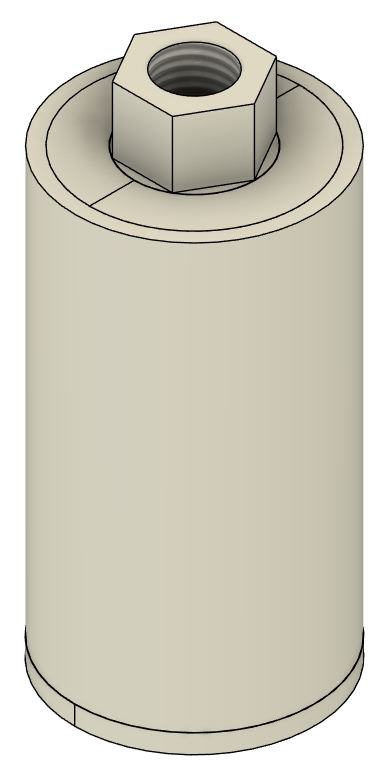

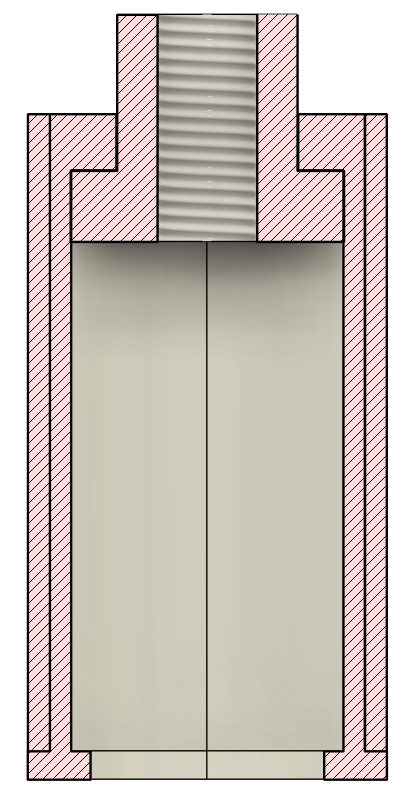

I wanted my gear puller to provide as much contact with the gear as possible to reduce the concentration of stress and hopefully . I came up with a design which uses two collets which come together to provide as close to full circular contact as possible. A sleeve fits around them to keep them together. A nut fits inside the collets and is acted on by a screw which pushes against the top of the shaft.

The construct of the collet allows the jaws to fit as close and deep as possible on the gear and have as much material as possible to support the pulling forces.

Construction

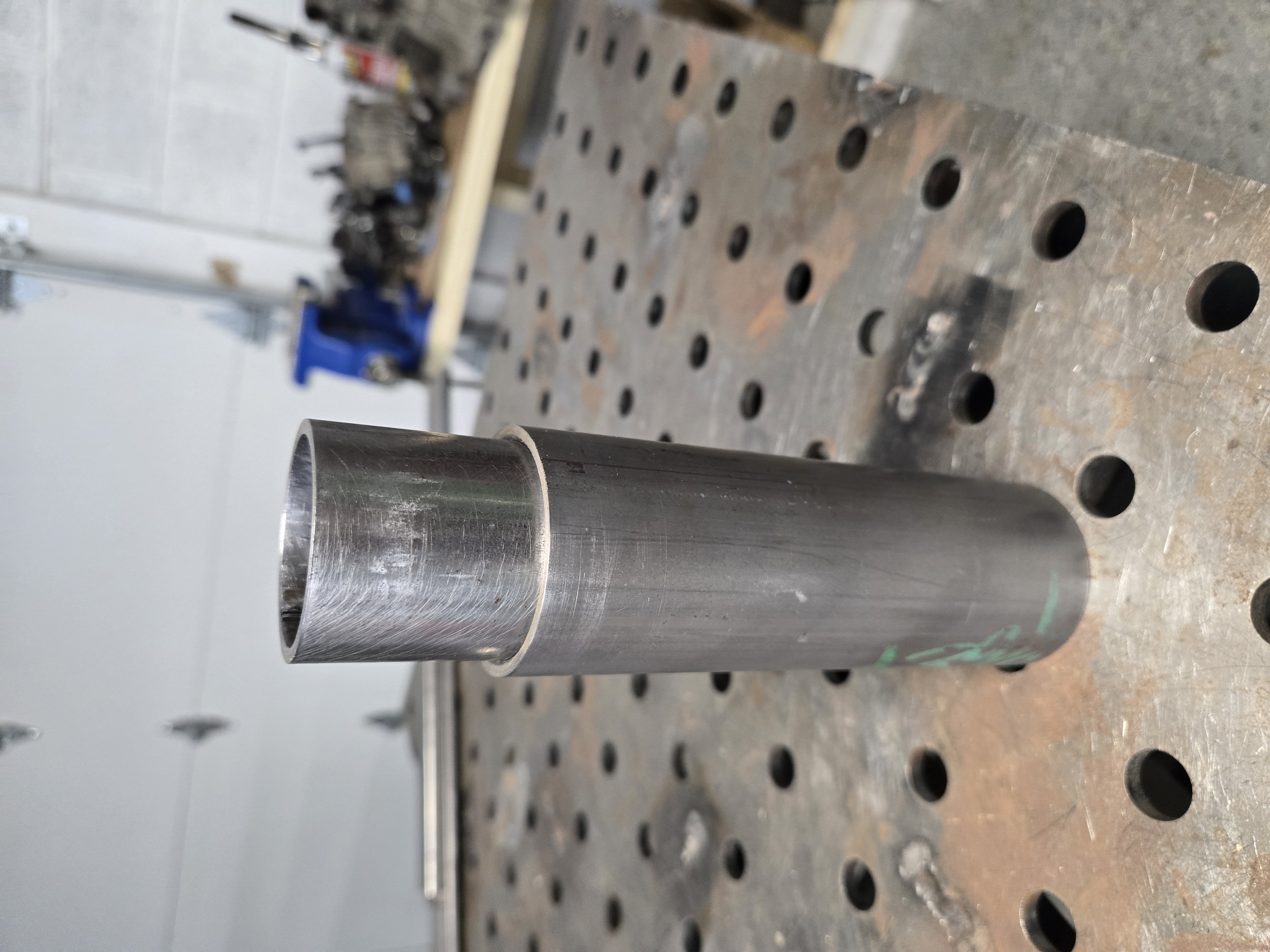

Once I’d drawn up a design I started working toward how to build it. I decided to make the collets by welding plates to a tube and cutting it in half. I picked the smallest available tubing which would fit over the gear. This ended up being 38.1 mm (1.5 inch) inside diameter. I decided on a 3.2 mm (0.125 inch) wall thickness, producing a 44.5 mm (1.75 inch) outside diameter.

For the sleeve, I chose the same wall thickness making for a 44.5 mm (1.75 inch) inside diameter, 3.2 mm wall thickness, and 50.8 mm (2 inch) outside diameter.

I was expecting available tubing to require some kind of clearancing to produce the required clearance, but found that the appropriately sized seamless tubing provided a clearance fit.

The tubing was cut to length and then squared up in the lathe.

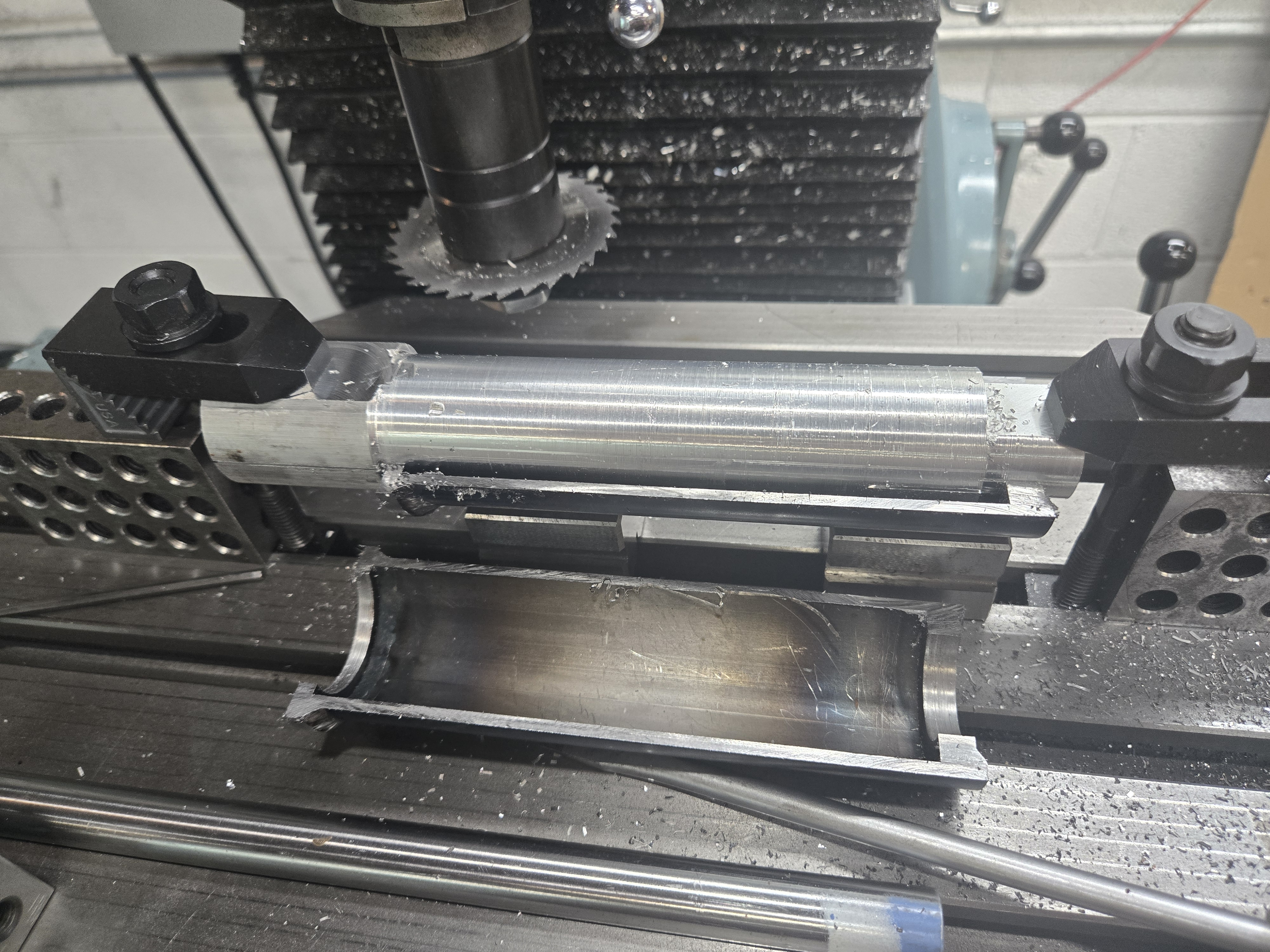

Plates were welded to the ends of the smaller tube, machined, and then slit to make the collets. The slitting operation required a mandrel.

A nut was machined.

The tube sprung some while slitting, as expected considering how it is manufactured. This made it a tighter fit in the sleeve than would be desired. Some massaging with files, sandpaper, and a bit of squeezing with a vise got it back in shape.

Operation

Using the gear puller involves putting the two collets over the gear and nut and the sleeve is dropped over the top. The screw is turned to push down on the shaft and pull up on the gear while the nut is held with a wrench.

Closing

The gear puller seemed to work well. The While it’s for a specific size of gear, it is quick and easy to manufacture. There’s a few more operations on this transmission which require a bespoke puller and I intend to make a few more for those cases.